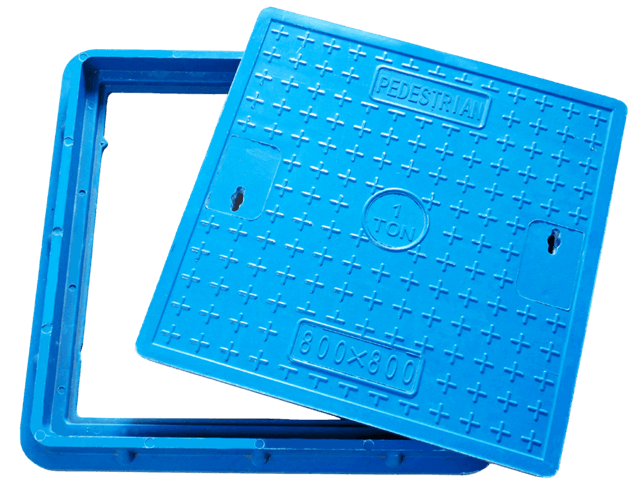

Commonly, manhole covers are made from cast iron. However, as technology advances, new materials that are used to make manhole covers are developed. The material is a composite (FRP). So, what are composite (FRP) manhole covers? What’s the difference between cast iron manhole covers? See the complete discussion below.

What are manhole covers?

Manhole covers are one of the drainage components that help to manage the hydrological cycle. With the continual climatic change, drainage system management and control must be carried out effectively, one of which is by using manhole covers.

Manhole covers are now commonly used, and there is a growing understanding of their long-term importance. However, the majority of manhole covers used are still made of cast iron, which has several drawbacks, including corrosiveness, heavy product mass, and theft.

What advantages of composite manhole covers have?

Manhole covers made of FRP materials are continually being researched as technology advances. They have several advantages, including:

- Easy to shape;

- Lightweight;

- Strong;

- The direction of the amplifier can be set.

- Low coefficient of thermal expansion;

- More vibration resistance;

- Corrosion resistance;

- Not prone to theft because it cannot be recycled.

Based on the material, what types of composite manhole covers are now available on the market?

Seal Plate made of FRP or GRP Manhole Covers

Both FRP (Fiberglass-Reinforced Plastics) and GRP (Glass-Reinforced Thermosetting Plastics) are composite materials that combine a thermosetting resin material (matrix) and glass fiber (glass fiber) to provide strength to the composite.

GRP is most commonly associated with European standards like ISO, EN, BS, DIN, and SFS. FRP is also utilized in American standards such as ASME and API.

FRP/GRP material is ideal for use as a manhole cover material since it possesses the following properties:

- Strong and light

- Not prone to rusting (corrosion resistance)

- Good insulating characteristics

- Difficult to heat

- Flexible (easy to shape)

Bulk Molding Compound (BMC) Manhole Covers

BMC is a type of composite material that is often used for manhole covers. BMC is made with unsaturated polyester resin, glass fiber, trays, steel rods, and calcium carbonate. The benefits of BMC include:

- being relatively easier and cheaper to manufacture

- having a smooth surface,

- being almost the same color.

Sheet Molding Compound (SMC) Manhole Covers

SMC, like BMC, is a composite material that is often used as manhole covers. The difference is in the more sophisticated manufacturing procedure, which results in a higher price.

Glass fiber, calcium carbonate, trays, unsaturated polyester resin, and certain additives are used to manufacture SMC. The advantage of SMC over BMC is that it has higher load-bearing strength.

Leave a Reply