Airport gratings are grates that we use at the sewage of the airport area. The use of grating in the airport area is usually in the area between the apron (airplane parking) and the taxiway (termite road to the runway).

Airport area needs rapid water absorption requiring an integrated drainage system. Water on the surface must immediately flow into the water channel to avoid puddles. The runway, taxiway, and apron should be free of puddles intended for flight safety.

A well-designed airport drainage system is a key need for operational safety and efficiency and asphalt road resistance. Inadequate drainage facilities may cause flooding, endanger air traffic, erosion, saturation, and weakening of asphalt road foundations.

Airport grating has special specifications considering its use is also in the special area of the airport. Here are the points related to the specifications of the airport grating.

Airport Gratings Specifications

1. Shape

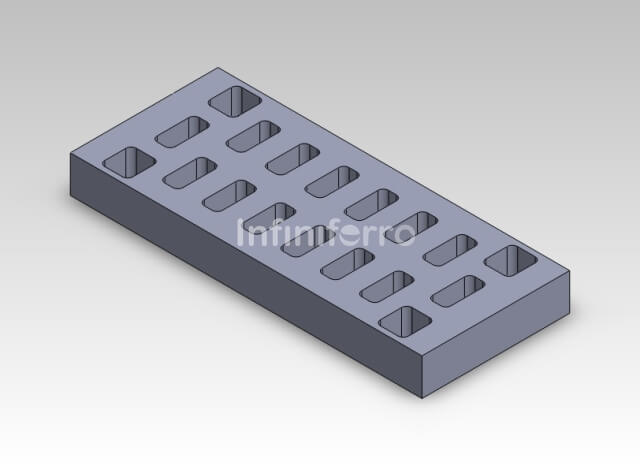

- Solid. Grating for use in the airport area should have a dominant design of body parts and without legs or base. It aims for long-term use. Grating without legs has better resistance because it has no space between the legs part.

- Rectangular. The shape of an airport grating is like a grating in general that is a rectangle with holes. For the grating size, you can adjust to the needs of the project.

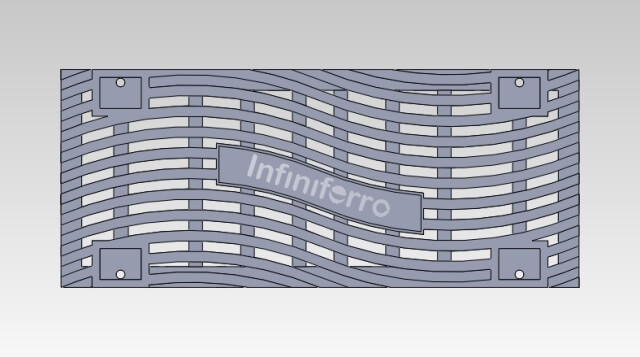

- Wavy type. In addition to the rectangular design with elongated holes, there is also an airport grating design with holes in the form of waves or water motifs. This design aims for decoration.

2. Perforated Design

Gratings have a vented design for allows water to enter the drainage channel directly through the gratings. So as not to cause puddles around the runway area. Puddles on the runway can cause the wheels of the plane to slip.

The size of the hole on the gratings also needs to be considered. Should not be too big so that your feet or the vehicle’s wheel does not fall into the grating hole.

3. Ductile Iron Material

Ductile iron is used when gray cast iron does not have the load-bearing capabilities for a particular application. This material is often used in areas subjected to loads greater than H20 loading such as airports.

Gratings for the airport area should be made from a material that can hold the heavy load of the airplane so we can use ductile iron. Ductile iron has characteristics:

- Able to withstand heavy load

- Capable of damping vibration

- Stronger than gray cast iron

- Not brittle and not easy to crack

4. Use bolts to reinforce grating installation

Bolts serve to strengthen the grating installation on the foundation so it does not shake and shift when the plane passes. Besides bolts also serve to dampen vibration. So when the vehicles pass through, the gratings do not vibrate.

We recommend you use steel bolts. Steel bolts are hard and strong so they are suitable for use along the airport gratings.

5. Flat Installation

Each drainage castings of both manhole covers and gratings should be well-fitted and level to the surrounding area. It aims to avoid shock when the load passes.

The grounding concrete for the gratings should be flat or equal. The bottom of the gratings is attached perfectly to the bottom ground. This concrete foundation must be sturdy to be able to withstand the load of the gratings, as well as the loads that pass through it.

Conclusion: grating and drainage are required at airports

The existence of airport drainage aims to avoid hazards, property damage, losses, and other expenses caused by puddles. The airport drainage system works to:

- Drain the airport area from puddles

- Controlling excessive accumulation of rainwater

- Controlling erosion

ALSO READ:

Dear CS,

I am unofficially engaged to design painting shed on existing concrete pavement.

The incoming door of the shed needs floor drainage since the pavement sloped in.

I think Infinerro drain cover suitable for this drainage.

Kindly, i want keep in touch with you.

Thank you,

Jurie

Batam

Hello Mr. Jurie,

Thank you for contacting us. We will send information about the drain cover via email.

Regards,

Marketing Team